Board assembly for third parties

Board assembly for third parties

MICROIDEA has been operating for many years in the board assembly sector for third parties and includes its historical customers in the most diverse fields: military, medical, food, avionics and telecommunications.

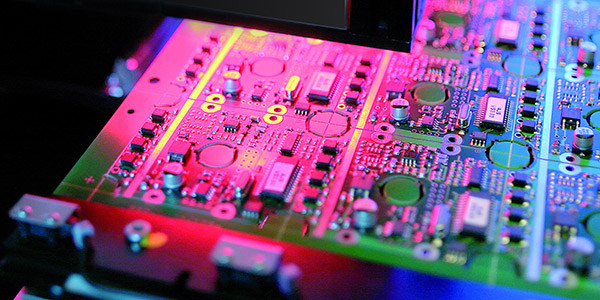

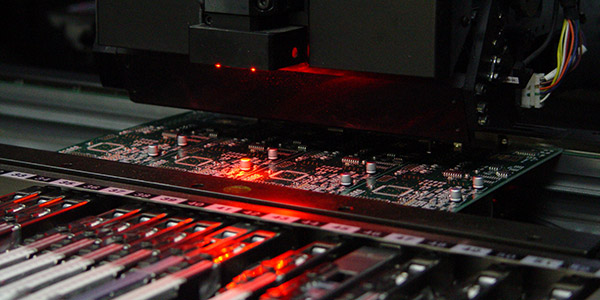

The assembly of the boards takes place with advanced RoHS processes, based on latest generation machines and highly reliable and repeatable equipment.

The SMT (Surface Mount Technology) process is fully automated both in the assembly and in the control phases. In this way it is possible to assemble not only irregularly shaped components, but also extremely small components such as 0402s.

The key phases of the SMT assembly process are 100% controlled by automatic systems:

- 3D Solder Paste Inspection: volumetric verification of the solder paste deposit;

- Automatic Optical Inspection: dimensional verification of the welds and positioning of the components according to the IPC-A-610 specification.

The manual THT assembly of the electronic boards is managed by expert and highly trained personnel, with 8 different assembly lines.

Microidea also deals with the design and supply of simple mechanical parts (heat sinks or metal containers) to support the electronics. The final assembly and functional testing service is usually performed following the specifications of our customers.

The traceability of each single production lot ensures the final customer the guarantee of the production process and the traceability of the lots for any after-sales need